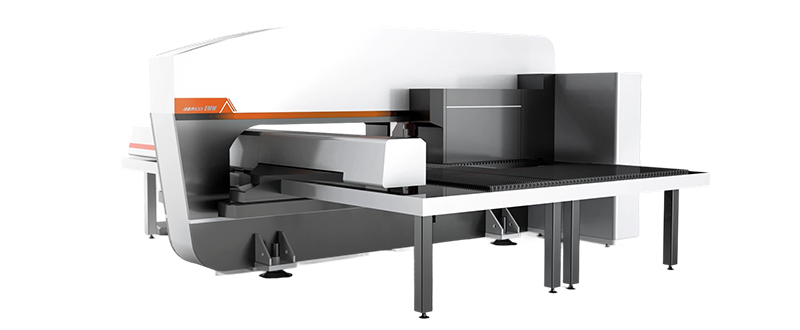

CNC turret punch press

1. High torque servo drive

Equipped with high-power servo motors to ensure smooth acceleration, precise punch control, and faster punching cycles to improve overall productivity.

2. Five-axis digital control and sub-layer programming

Advanced CNC technology controls X-Y positioning, turret indexing and punching depth, enabling complex part manufacturing and flexible small batch production.

3. Modular turret design

Each turret supports up to 6 tool stations, allowing for quick tool changes, minimizing downtime and extending tool life during continuous operation.

4. Precision transmission, low clearance

High-precision components provide positioning accuracy within ±0.1 mm and smaller gaps, ensuring consistent, high-quality stamping results.

5. Large working area

The standard working area is 2500 × 1250 mm and can be expanded to 2500 × 2000 mm to accommodate larger sheets and efficient nesting of multiple parts.

6. Efficient material handling

Features automatic film clamping and waste separation system to optimize workflow and increase throughput on high-volume production lines.

The WME series CNC turret punch press is an advanced solution for fast and precise sheet metal stamping. With a five-axis digital control system, a powerful servo drive mechanism, and a modular turret design, this machine provides exceptional precision, reliability, and efficiency. Designed to meet the demands of demanding industrial applications, the WME series offers a variety of tooling capabilities and delivers consistent, high-quality results in complex stamping operations.

Key Features and Benefits

1. High torque servo drive

Equipped with high-power servo motors to ensure smooth acceleration, precise punch control, and faster punching cycles to improve overall productivity.

2. Five-axis digital control and sub-layer programming

Advanced CNC technology controls X-Y positioning, turret indexing and punch depth, enabling complex part manufacturing and flexible small batch production.

3. Modular turret design

Each turret supports up to 6 tool stations, allowing for quick tool changes, minimizing downtime and extending tool life during continuous operation.

4. Precision transmission, low clearance

High-precision components provide positioning accuracy within ±0.1 mm and smaller gaps, ensuring consistent, high-quality stamping results.

5. Large working area

The standard working area is 2500 × 1250 mm and can be expanded to 2500 × 2000 mm to accommodate larger sheets and efficient nesting of multiple parts.

6. Efficient material handling

Features automatic film clamping and waste separation system to optimize workflow and increase throughput on high-volume production lines.

Technical overview

specification |

And give me/give me |

And not 0B/334B/damaged |

And the mea4s/330s/334s/sneeze |

punching force |

250 kN |

250 kN |

250 kN |

turret station |

30/36 tools |

30/30/36 tools |

24/30/30/36 tools |

Each turret indexing station |

4/A |

2/4/2 |

4/2/4/2 |

Maximum travel |

32 mm |

32 mm |

32 mm |

Maximum plate thickness |

6 mm |

6 mm |

6 mm |

Working area (X×Y) |

2500 × 1250 mm |

2500 × 1500 mm |

2500 × 2000 mm |

Maximum feed speed of worktable |

113m/min |

113m/min |

113m/min |

Maximum film weight |

150 kg |

150 kg |

150 kg |

Punching speed (6mm stroke) |

to 350 h/min |

up to 320 h/min |

up to 320 h/min |

Positioning accuracy |

±0.1 mm |

±0.1 mm |

±0.1 mm |

Repeatability |

±0.05 mm |

±0.05 mm |

±0.05 mm |

Turret speed |

30rpm |

30rpm |

30rpm |

Power consumption (average) |

< 5 kW |

< 5 kW |

< 5 kW |

Machine weight |

16–19 ton |

17–19 ton |

19 ton |

Application areas

1.Automobile and aerospace parts

Precision stamping of complex hole patterns and contours is critical for automotive and aerospace parts, meeting tight tolerances and ensuring consistent quality.

2. Electrical enclosures and cabinets

Providing fast turret indexing to efficiently create multi-hole layouts, ideal for manufacturing control panels, switchgear and a variety of electrical cabinets.

3. HVAC and piping system manufacturing

Supports large-format stamping combined with automated material handling to enable fast, high-volume production of ducts, vents, and HVAC components.

4. Architectural metal products

Produce detailed patterns, louvers and decorative perforations with CNC precision, perfect for custom architectural panel and metal facade applications.

Company Profile

Shandong Workman Industrial Equipment Co., Ltd. takes "leading technology and excellent service" as its corporate philosophy. The company has a 5,000 square meter production base in Changzhou Wujin National High-tech Zone to provide services to customers in East China. In order to better serve the South China market, Workman has set up a 500 square meter 4S showroom in Shunlian International Machinery City, Foshan, Guangdong.

Walkerman is committed to continuous innovation and has established a dedicated R&D center in Jinan, focusing on integrating automation and digitalization technologies into the sheet metal processing industry. This ensures that the Walkerman product line is always at the forefront of intelligent manufacturing solutions.

The company's major shareholder, Dongguan Jiangshi Industrial Investment Partnership, brings together partners from listed multinational company management teams and leading domestic research institutions. With more than 20 years of experience in mechanical manufacturing, this skilled and visionary team works closely with customers to promote the development of intelligent manufacturing in China's sheet metal industry.

Why choose Workman?

With cutting-edge servo-driven turret punch press technology, advanced CNC controls and powerful modular tooling, Workman delivers industry-leading speed, precision and uptime - the perfect modern sheet metal stamping solution.