What is the application of laser tube cutting machine in tube processing?

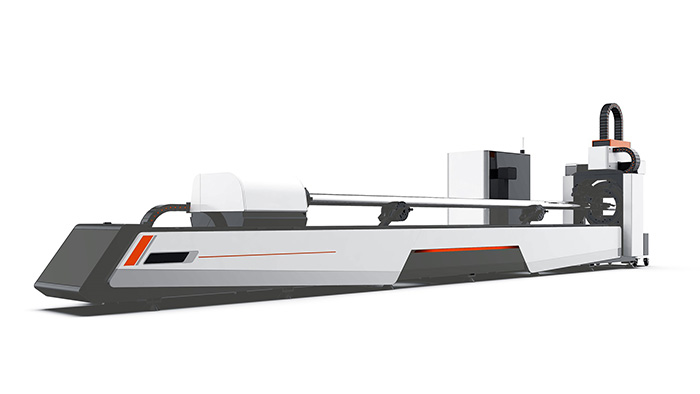

With the continuous advancement of industrial technology, laser tube cutting machines, as an efficient and precise processing equipment, have been widely used in the field of tube processing. Laser tube cutting machines use high-energy-density laser beams to cut tubes. They have the advantages of fast cutting speed, high precision, and good cutting quality, and can meet the processing needs of complex shapes and high-precision requirements.

1. Working principle of laser tube cutting machine

The working principle of the laser tube cutting machine is mainly to generate a high-energy-density laser beam through a laser generator, which is focused by an optical system to form a high-power-density laser beam and irradiate the surface of the tube. The laser beam interacts with the surface of the tube to quickly melt, vaporize or reach the ignition point of the material, and at the same time, the molten material is blown away by auxiliary gases (such as oxygen, nitrogen, etc.), thereby achieving cutting. Laser tube cutting machines are usually equipped with a CNC system that can automatically complete the cutting task of complex shapes according to the preset cutting path and parameters.

2. Advantages of laser tube cutting machine

High-precision cutting: The laser tube cutting machine can achieve micron-level cutting accuracy, the incision is smooth and burr-free, and no subsequent processing is required, which greatly improves processing efficiency and product quality.

Fast cutting speed: The speed of laser cutting is much higher than that of traditional mechanical cutting methods, especially when cutting thin-walled pipes, the efficiency improvement is particularly significant.

Strong adaptability: Laser tube cutting machines can cut a variety of materials, such as stainless steel, carbon steel, aluminum alloy, copper, etc., and can adapt to tubes of different shapes and sizes.

High degree of automation: Laser tube cutting machines are usually equipped with CNC systems, which can realize automatic operation, reduce manual intervention, reduce labor intensity and improve production efficiency.

Environmental protection and energy saving: No tools are required during the laser cutting process, which reduces tool wear and the frequency of replacement. At the same time, laser cutting produces less waste, which meets environmental protection requirements.

3. Application fields of laser tube cutting machine

Automobile manufacturing: In the automobile manufacturing industry, laser tube cutting machines are widely used in the processing of automobile chassis, exhaust systems, body structures and other parts. Laser cutting can achieve precise cutting of complex shapes and meet the high-precision requirements of automobile parts.

Aerospace: The aerospace field has extremely high requirements on material processing accuracy and quality. Laser tube cutting machines can cut high-strength and high-hardness alloy materials to meet the processing needs of aerospace components.

Construction industry: In the construction industry, laser tube cutting machines are used to cut steel tubes, stainless steel tubes, etc. in building structures. They can achieve fast and precise cutting and improve construction efficiency.

Medical devices: Medical devices have extremely high requirements for material processing accuracy and hygiene. Laser tube cutting machines can cut stainless steel, titanium alloy and other materials to meet the high-precision processing needs of medical devices.

Petrochemical: In the petrochemical industry, laser pipe cutting machines are used to cut pipes, valves and other components. They can achieve fast and precise cutting and improve the efficiency of equipment installation and maintenance.

4. Future development trend of laser tube cutting machine

Intelligent development: With the development of artificial intelligence and Internet of Things technology, laser tube cutting machines will develop in the direction of intelligence, realizing functions such as remote monitoring, fault diagnosis, and automatic optimization of cutting parameters, thereby improving the intelligence level of the equipment.

Application of high-power lasers: With the continuous advancement of laser technology, the application of high-power lasers will further improve the cutting speed and efficiency of laser tube cutting machines and expand their application scope.

Multifunctional integration: The future laser tube cutting machine will not only be limited to the cutting function, but will also integrate multiple functions such as punching, welding, surface treatment, etc. to achieve multifunctional integrated processing.

Green and environmental protection: With the continuous improvement of environmental protection requirements, laser tube cutting machines will pay more attention to energy conservation and emission reduction, reduce waste and pollution during the cutting process, and promote the development of green manufacturing.

Customized service: With the diversification of market demand, laser tube cutting machines will provide more customized services to meet the personalized needs of different industries and customers.