Which industries are laser cutting machines suitable for?

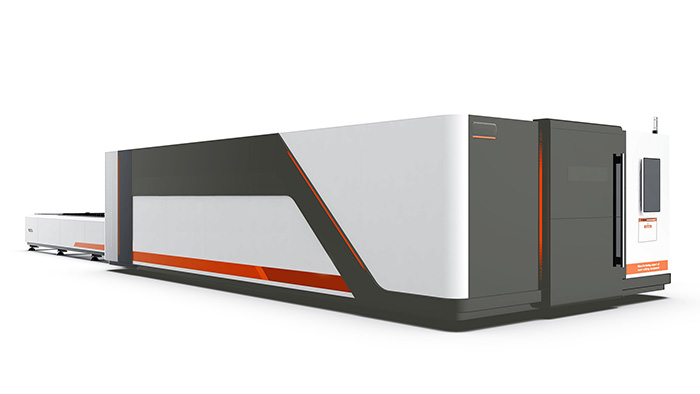

As an efficient and precise processing equipment, laser cutting machine plays a vital role in modern manufacturing. It cuts materials through high energy density laser beams, and has the advantages of fast cutting speed, high precision, and smooth incision, so it has been widely used in many industries. The following will introduce in detail the industries suitable for laser cutting machines and their specific applications.

1. Metal processing industry

Metal processing industry is one of the main application areas of laser cutting machines. Laser cutting machines can efficiently cut various metal materials, such as stainless steel, carbon steel, aluminum alloy, copper, titanium alloy, etc. Its high precision and high efficiency make it widely used in the following aspects:

Sheet metal processing: Laser cutting machines are used to cut metal plates of various shapes in sheet metal processing and are widely used in the manufacture of chassis, cabinets, electrical housings and other products.

Automobile manufacturing: In the automobile manufacturing process, laser cutting machines are used to cut body panels, chassis components, engine parts, etc., which improves production efficiency and product quality.

Aerospace: The aerospace field has extremely high requirements on the precision and strength of materials. Laser cutting machines can accurately cut high-performance materials such as titanium alloys and aluminum alloys for manufacturing aircraft parts and spacecraft structures.

2. Electronics and electrical industry

The electronics and electrical industry has extremely high requirements for the precision and surface quality of parts, and laser cutting machines have significant advantages in this regard. Its applications include:

Circuit board manufacturing: Laser cutting machines are used to cut circuit boards to ensure accurate size and smooth edges, improving the performance and reliability of circuit boards.

Electronic components: Laser cutting machines are used to cut the shells and brackets of various electronic components, such as the shells and internal structural parts of mobile phones, computers, televisions and other electronic products.

Sensor manufacturing: Sensors have extremely high precision requirements. Laser cutting machines can accurately cut sensor housings and internal parts to ensure the performance and stability of the sensors.

3. Textile and clothing industry

The application of laser cutting machines in the textile and garment industry is mainly reflected in fabric cutting and pattern engraving. Its advantages include:

Fabric cutting: Laser cutting machines can accurately cut a variety of fabrics, such as cotton, linen, silk, chemical fiber, etc. The cutting edges are smooth and burr-free, which improves the quality and aesthetics of clothing.

Pattern engraving: Laser cutting machines can perform fine pattern engraving on fabrics, which can be used to make high-end clothing, home textile products, etc., thus increasing the added value of the products.

Leather processing: Laser cutting machines are used to cut and engrave leather to make high-end leather goods, shoes, bags, etc., improving the fineness and aesthetics of the products.

4. Advertising and logo industry

The advertising and signage industry has high requirements for cutting accuracy and surface quality of materials, and laser cutting machines have significant advantages in this regard. Its applications include:

Acrylic cutting: Laser cutting machines can accurately cut acrylic sheets for making billboards, signboards, light boxes, etc. The cutting edges are smooth and burr-free, which improves the aesthetics of the product.

Metal signs: Laser cutting machines are used to cut metal signs, such as stainless steel, aluminum plates, etc., to make various logo plates, nameplates, medals, etc., improving the accuracy and aesthetics of the products.

Wood cutting: Laser cutting machines are used to cut wood and make various billboards, signboards, decorations, etc., which improves the fineness and aesthetics of the products.

5. Medical device industry

The medical device industry has extremely high requirements for material precision and hygiene, and laser cutting machines have significant advantages in this regard. Its applications include:

Surgical instruments: Laser cutting machines are used to cut and process various surgical instruments, such as scalpels, scissors, tweezers, etc., ensuring the accuracy and hygiene of the instruments.

Medical equipment: Laser cutting machines are used to cut and process the outer shells and internal parts of various medical equipment, such as CT machines, X-ray machines, ultrasound equipment, etc., improving the performance and reliability of the equipment.

Implant manufacturing: Laser cutting machines are used to cut and process various implants, such as artificial joints, dental implants, etc., ensuring the precision and biocompatibility of the implants.

6. Building decoration industry

The architectural decoration industry has high requirements for cutting accuracy and surface quality of materials, and laser cutting machines have significant advantages in this regard. Its applications include:

Metal decoration: Laser cutting machines are used to cut various metal decorative materials, such as stainless steel, aluminum plates, etc., to make various decorative panels, screens, railings, etc., which improves the beauty and refinement of the products.

Stone cutting: Laser cutting machines are used to cut various stones, such as marble, granite, etc., to make various decorative panels, sculptures, tombstones, etc., which improves the fineness and beauty of the products.

Glass cutting: Laser cutting machines are used to cut various types of glass, such as tempered glass, laminated glass, etc., to make various decorative panels, partitions, doors and windows, etc., improving the fineness and aesthetics of the products.

7. Packaging and printing industry

The packaging and printing industry has high requirements for cutting accuracy and surface quality of materials, and laser cutting machines have significant advantages in this regard. Its applications include:

Cardboard cutting: Laser cutting machines are used to cut various cardboards and make various packaging boxes, gift boxes, display stands, etc., which improves the fineness and aesthetics of the products.

Plastic cutting: Laser cutting machines are used to cut various plastics, such as PVC, PET, etc., to make various packaging boxes, bottle caps, labels, etc., which improves the fineness and aesthetics of the products.

Label production: Laser cutting machines are used to cut various label materials, such as stickers, films, etc., to produce various labels, nameplates, logos, etc., which improves the fineness and aesthetics of the products.

8. Furniture manufacturing industry

The furniture manufacturing industry has high requirements for cutting accuracy and surface quality of materials, and laser cutting machines have significant advantages in this regard. Its applications include:

Wood board cutting: Laser cutting machines are used to cut various wood boards and make various furniture, cabinets, wardrobes, etc., which improves the fineness and aesthetics of the products.

Metal furniture: Laser cutting machines are used to cut various metal materials, such as stainless steel, aluminum plates, etc., to make various metal furniture, brackets, decorative parts, etc., which improves the fineness and aesthetics of the products.

Soft package cutting: Laser cutting machine is used to cut various soft package materials, such as sponge, leather, etc., to make various soft package furniture, sofas, mattresses, etc., which improves the fineness and aesthetics of the products.