CNC bending machine

1. Powerful hydraulic drive system

Adopts stable and efficient hydraulic system to provide strong and consistent pressure. Precision hydraulic valve ensures smooth motion control and reliable pressure regulation throughout the bending process.

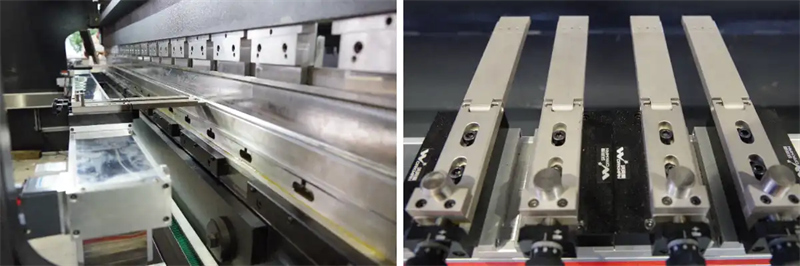

2. Extended guide rails and stable force distribution

Equipped with extra-long linear guides and high-response proportional valves, it ensures uniform pressure throughout the entire bend length, improving part accuracy and repeatability.

3. Heavy frame structure

Built with an integrated, high-rigidity steel frame, designed to reduce deformation under heavy workloads. This rugged structure improves long-term durability and minimizes maintenance.

4. Precision CNC control, real-time adjustment

The advanced CNC system can automatically adjust the bending parameters, including back-setting positioning and angle correction, ensuring the accuracy of complex part geometries within ±0.1°.

5.Wide range of specifications

Available in a range of sizes from 3 × 1250mm to 25 × 4100mm, with press capacities from 350kN to 3200kN, these machines can handle a wide range of sheet thicknesses and applications, from light to heavy bending.

6. Efficient production performance

Optimized cycle speeds and intelligent hydraulic flow control reduce idle time and increase operating efficiency, ideal for both mass production and custom job shop work.

Product introduction

Workman's CNC press brakes combine powerful hydraulic power with intelligent CNC controls to deliver accurate, repeatable bending results in a wide variety of metal fabrication tasks. Designed for manufacturers who prioritize durability, consistent performance, and cost-effective operation, these machines are ideal for high-demand production environments. With optimized cycle times and reliable pressure control, Workman's CNC hydraulic press brakes ensure stable, efficient, and high-quality sheet metal forming.

Key Features and Benefits

1. Powerful hydraulic drive system

Adopts stable and efficient hydraulic system to provide strong and consistent pressure. Precision hydraulic valve ensures smooth motion control and reliable pressure regulation throughout the bending process.

2. Extended guide rails and stable force distribution

Equipped with extra-long linear guides and high-response proportional valves, it ensures uniform pressure throughout the entire bend length, improving part accuracy and repeatability.

3. Heavy frame structure

Built with an integrated, high-rigidity steel frame, designed to reduce deformation under heavy workloads. This rugged structure improves long-term durability and minimizes maintenance.

4. Precision CNC control, real-time adjustment

The advanced CNC system can automatically adjust the bending parameters, including back-setting positioning and angle correction, ensuring the accuracy of complex part geometries within ±0.1°.

5. Wide range of specifications

Available in a range of sizes from 3 × 1250mm to 25 × 4100mm, with press capacities from 350kN to 3200kN, these machines can handle a wide range of sheet thicknesses and applications, from light to heavy bending.

6. Efficient production performance

Optimized cycle speeds and intelligent hydraulic flow control reduce idle time and increase operating efficiency, ideal for both mass production and custom job shop work.

Technical overview

model |

WMF312 |

WMF620 |

WMF1031 |

And revealing |

WMF1132/WMF1141 |

WMF1732/WMF1741 |

And Mafakh/Mafakh41 |

WMF3232/WMF3241 |

bending force |

350 kN |

600 kN |

1000 kN |

800 kN |

1100 kN |

1700 kN |

2500 kN |

3200 kN |

working length |

1250 mm |

2000 mm |

3100 mm |

2500 mm |

3200 mm |

4100 mm |

4100 mm |

4100 mm |

Entrance depth |

1020 mm |

1720 mm |

2550 mm |

2000 mm |

2700 mm |

3600 mm |

3600 mm |

3600 mm |

Adjust stroke |

200 mm |

160 mm |

225 mm |

240 mm |

265 mm |

265 mm |

265 mm |

265 mm |

working speed |

46 mm/s |

52 mm/s |

58 mm/s |

200 mm/s |

180 mm/s |

130 mm/s |

110 mm/s |

110 mm/s |

deformation |

≤ 395 mm |

≤ 425 mm |

≤ 500 mm |

≤ 500 mm |

≤ 500 mm |

≤ 500 mm |

≤ 500 mm |

≤ 500 mm |

CNC control |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

Machine weight |

2000 kg |

3800 kg |

6600 kg |

9800 kg |

11000 kg |

13400 kg |

16000 kg |

18500 kg |

power supply |

10kVA |

16kVA |

16kVA |

26 kVA |

26 kVA |

26 kVA |

26 kVA |

26 kVA |

Application areas

1.Automobile body parts and chassis parts

Suitable for forming large automotive parts such as body panels, frames, chassis structures, etc. The CNC hydraulic system ensures strong punching force and dimensional consistency, which is critical to automotive production standards.

2.Electrical cabinet and control box

Providing stable bends for switch cabinets, control boxes, switchboards. Suitable for small to medium batch production where clean angles and repeatable accuracy are essential.

3. HVAC ducts and support structures

Ideal for high-speed manufacturing of HVAC components such as ventilation ducts, brackets and support arms. The machine's efficient hydraulic control increases throughput in large-scale production.

4. Architectural and decorative metal products

Handle custom designs, complex geometries, and decorative bends with CNC-guided precision. Perfect for architectural cladding, trim, signage, and interior metal features that demand both form and function.

Company Profile

Shandong Workman Industrial Equipment Co., Ltd. adheres to the core concept of "leading technology and excellent service". The company has a 5,000 square meter production base in Changzhou Wujin National High-tech Zone, serving customers in the entire East China region. In order to expand the support network, Workman has also established a 500 square meter 4S showroom in Foshan Shunlian International Machinery City to provide localized display, consultation and after-sales service.

In order to stay at the forefront of innovation, Workman has set up a dedicated R&D center in Jinan, focusing on integrated automation and digitalization technologies for sheet metal processing. This enables the company to continuously develop cutting-edge equipment and intelligent solutions.

The company has received strong support from its major shareholder, Dongguan Jiangshi Industrial Investment Partnership, whose team has more than 20 years of industry experience.