Sheet metal processing

Sheet metal processing covers the cutting, forming and splicing of metal sheets, and is widely used in industrial housings, chassis cabinets, architectural decoration and other fields. The thickness of carbon steel, stainless steel, aluminum alloy and other plates is between 0.5-20 mm, and high requirements are placed on cutting accuracy, slit quality and shape. Laser cutting machines have the advantages of high penetration and extremely fine slits, which can meet a variety of thickness requirements; CNC turret punch presses are suitable for efficient punching and blanking; servo bending machines are used for high-precision forming. Combined with fully automatic loading and unloading and stacking systems, it can take into account both small batch diversity and large-scale production, reduce labor by more than 30%, and significantly improve production cycle and cost-effectiveness.

Recommended equipment:

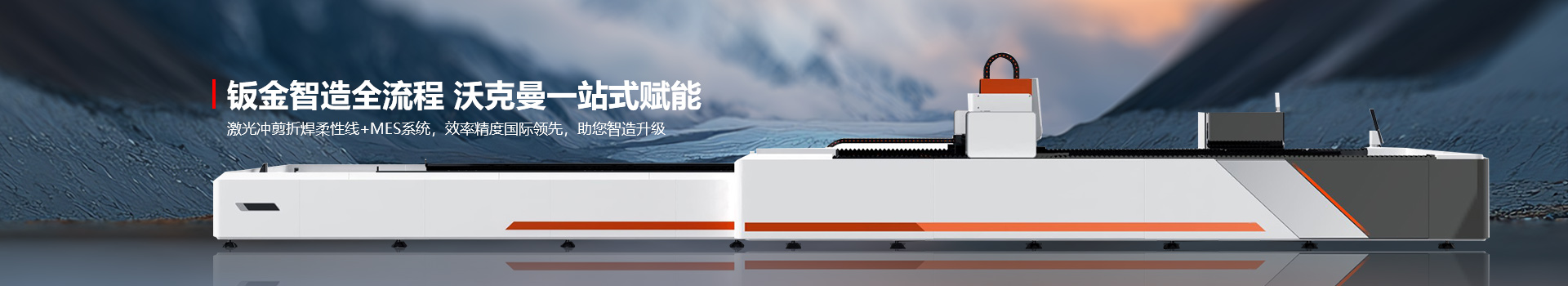

Medium and high power fiber laser cutting machine

High precision CNC turret punch press

Medium and high tonnage servo bending machine

Automatic loading and unloading and three-dimensional warehouse